Map Test #2

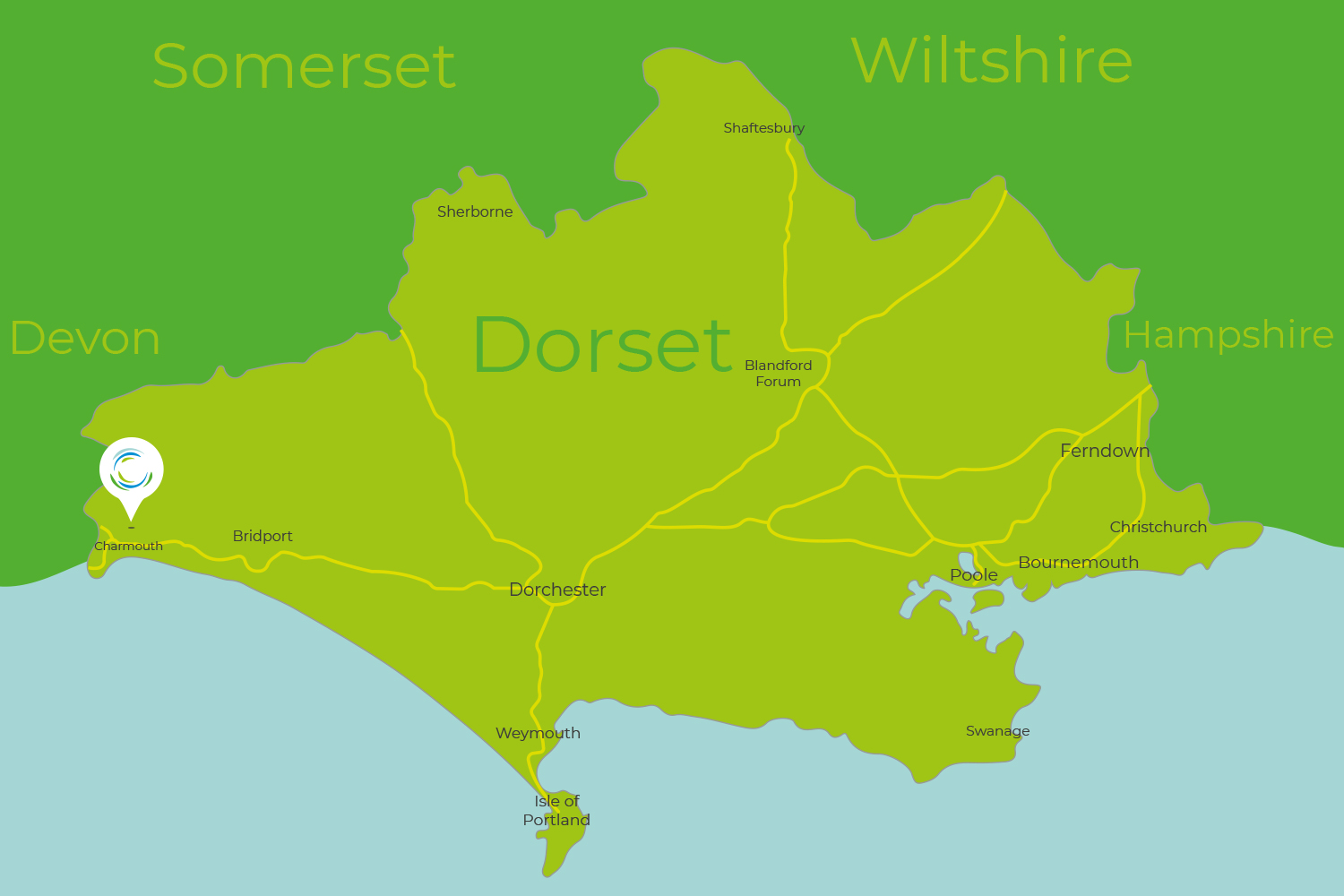

Location: Hooke Park, Hooke, Beaminster, Dorset, DT8 3PH

Type of Low Carbon Technology: Biomass Boiler, district heating system and self-supply woodfuel

Project Contact: Jeremy Ralph, Estate Manager Hooke Park Jeremy.ralph@aaschool.ac.uk

Project Overview: Hooke Park is the rural campus of the Architectural Association School of Architecture. The campus acts as a teaching venue and an evolving experiment in design and make architecture. The growing campus is largely built as student design projects using timber from the estate’s 130ha woodland, and comprises of workshops and accommodation.

The boiler is a 200kW Guntamatic biomass boiler, installed in 2014. The boiler supplies heat via a district heating system to buildings of a variety of sizes; from a large workshop to small student lodges. The campus is expanding regularly and new extensions are added to the district heating system as and when new buildings go up.

The boiler house, at the heart of the campus is an experimental architectural structure designed and built by students using low-quality roundwood thinnings supplied from the forest, and uses minimal processing to produce a low-embedded-carbon structure. The boiler house also contains a 35m3 chip store.

Fuel is self-supplied from the forest. Harvested and seasoned roundwood is brought to a central site and chipped by a contract chipper once a year into a bulk chip store two hundred meters from the boiler house. The bulk chip store, like the boiler house, is constructed from low-value timber from the forest.

Suppliers of technologies installed: 200kW Guntamatic biomass boiler installed by Treco in 2014

How was the project developed? An initial feasibility study was carried out by Forest Fuels which provided the main source of information to go to the finance, estates & infrastructure teams at the main school in London. This was accompanied by a cost-benefit analysis considering capital costs, RHI payments and fuel savings.

Once permission to go ahead had been given the installation was put out to tender with 6 organisations submitting tenders. Uniquely the tender had a clause in it to consider the way the contractor would work with the students who would be designing and building the boiler house. Besides this we asked for a turnkey solution for boiler and district-heating installation.

The system designed by Treco and the boiler-house designed by AA students went hand-in-hand, and planning permission was granted for the boiler house.

How was the technology installed? Installation was undertaken in a number of distinct phases:

- Trenching and installation of heat-main system to all buildings. We used this as an opportunity to rationalise other site services and bring services into central service spines with strategically placed hubs into which new buildings could be plugged in as and when they were built.

- Building of the boiler house was a design & make brief to a group of 2 students who worked alongside tutors and volunteers to construct the building.

- Installation of the boiler, thermal store and systems. This happened alongside the building of the boiler house. Due to design constraints the boiler was installed before the roof of the boiler house went on, and therefore had to be protected whilst building works carried on around it.

How is the technology run and maintained? After an initial 18-month bedding in period the boiler runs with little intervention. The boilerhouse’s 35m3 chip store is filled as necessary from the bulk chip store which holds a year of chip. Annual and monthly maintenance takes place.

The yard manager takes responsibility for the boiler and has become proficient in diagnosing and dealing with problems or regular maintenance issues.

Issues experienced with the technology, its installation, and the ongoing maintenance: The initial installation appeared to go smoothly, however on commissioning problems were found. These problems largely related to how the boiler house system was configured; whether the thermal store was in fact a thermal store or a buffer tank and also damage inside the boiler.

All issues have now been resolved, however it took 18 months to get the boiler working properly. In the future we would choose an installer that had a long background in commercial boiler installations and evolved to biomass, rather than an installer that had come into commercial boilers via biomass. This is due to the fact the boilers themselves are pretty much plug-and-play, but the systems are complicated.

One significant issue with the boiler is that we had assumed it would be a fully on-line system that could be monitored and adjusted remotely. This hasn’t been the case, and Gutamatic & Treco have not been able to resolve this. This means that monitoring efficiency of the system is virtually impossible.

In the first year we bought in chip and were incredibly thankful we had taken advice on chip-store configuration from Forest Fuels. The first batch of chip we got was very damp, and had we not been timber experts we may not have picked this up. The issue was quickly resolved and didn’t occur again.

Self-supply of woodchip hasn’t been an issue but we have had to re-evaluate and change our harvesting and timber sales patterns. The need to season the timber before chipping means that timber needs need to be assessed up to two years in advance of use.

Benefits of the technology: A benefit from the technology has been the income from RHI. The self-supply aspect has significantly cuts fuel costs.

Moving from a multi-fuel solution on a building by building basis to centralised heat and a single boiler has been the main advantage from an estate management basis.

Cost of technology (including installation and ongoing maintenance): For exact pricings for this project please get in touch with the project contact directly.

How was the project funded? The costs were funded in-house through a long-standing donation to the AA for works at Hooke Park. Because the original donation hadn’t included this work, but was earmarked for other areas of the campus, RHI payments are fed back into this designated fund.

Lessons learned from this project: We would have used a heat system specialist who had moved into biomass, rather than specifically a biomass installer.

We project managed the boiler house build and installation in-house and would do so again, however if doing over again we would bring in an independent expert at the end of the installation to check the system on our behalf before signing off the job with the installer.